This year we carefully created a PU leather handle coffee tin box for the coffee brand. The size is 185x136x85mm. It is made of food-grade tinplate and the material thickness is 0.23mm.

This year, Cosmetics Brands joined hands with our professional tin box manufacturer to create a cosmetic tin box with handle that combines beauty and practicality. This is not only a container for beautiful things, but also an ode to a refined attitude towards life.

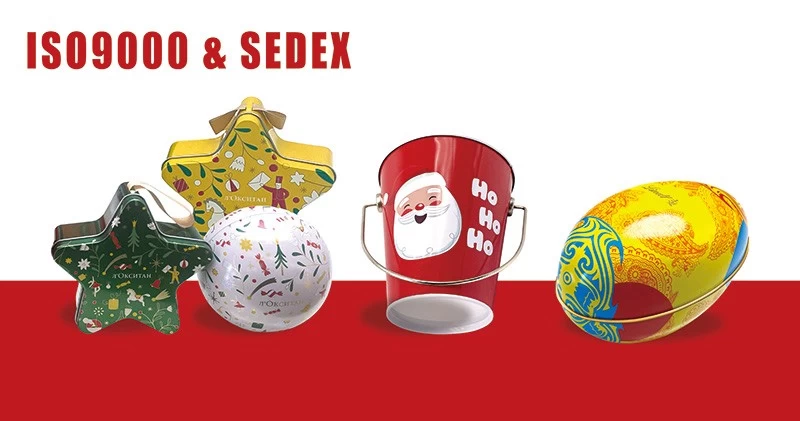

The Xmas detachable candy balls is made of tinplate, the iron box is strong and durable. It is not easy to open directly, you can easily open the hemisphere without the string by pulling the string. The Christmas ball can be used as a candy jar, and the candy ball has enough space for candies, chocolates, trinkets, and small things. At the same time, its lovely shape and hanging ribbon are also perfect for Christmas tree decoration

Material and safety Food-grade tinplate material, light and durable, drop-proof and rust-proof, in line with food safety standards. The interior adopts environmentally friendly coating, no odor, and can directly contact food. Customized printing Full-surface high-definition printing: supports single-sided/double-sided customization of corporate logos, patterns, slogans or art designs. Process selection: silk screen printing, hot stamping, UV embossing and other processes are optional to enhance the brand texture. Applicable scenarios: employee benefits, event gifts, promotional gifts, campus customization, etc.

Our round tin cookie box is an elegant and practical packaging solution designed to keep your cookies fresh and beautifully presented. Made from high-quality tinplate, it offers excellent durability and protection against moisture and breakage. The smooth, classic round shape adds a touch of sophistication, making it perfect for gifts, festive treats, or everyday storage. With customizable designs, sizes, and finishes, this tin box not only preserves the delicious taste of your cookies but also enhances your brand’s image with eye-catching, reusable packaging.

This heart-shaped tin box is made from food-grade material, making it safe for storing a variety of candies and gifts. Perfect for the holiday season, this charming tin adds both function and holiday cheer to any celebration.

These discreet low profile rectangle tins feature a clean & fresh style that will remain modern for many uses to come. Our lightweight durable containers are made from high-quality material. Reliable hinge & seal for a perfect closure every time. General household organizing, crafts, homemade packaging, store spices, tea leaves, coffee beans, chocolates, mints, creams, balms, gels, jewelry, beads, sequins, recipe cards, arts, medicines, pills, lip balm, cosmetics, gifts, party favors, Double button locking hinged lid that offers great child resistant packaging.

Designed for exquisite chocolates, our custom food-grade rectangular chocolate tinplate boxes provide safe, beautiful and highly flexible packaging solutions. This packaging box is strictly made of high-quality tinplate materials that meet food contact safety standards (such as FDA/GB) to ensure that the contents are pure and uncontaminated. The classic rectangular design is not only simple and elegant in appearance and full of modernity, but also can efficiently utilize space, making it easy to stack, transport and retail display. The core advantage lies in its deep customization service - you can freely choose the box size, color (internal and external coating), pattern printing (high-definition color printing, hot stamping/silver, etc.), and lining material (such as food-grade white cardboard tray, PET blister tray, flannel, etc.), perfectly carrying and enhancing the value and protection of your brand chocolate. The sturdy iron box structure provides excellent sealing and moisture-proof performance, effectively extending the freshness and shelf life of chocolate, and is an ideal packaging choice for high-end chocolate brands, gift markets and baking industries.

Custom printed tin boxes are not only high-quality packaging solutions, but also mobile brand billboards. This article will explore the advantages of China's leading manufacturers, the core competitiveness of Guangdong supply chain, the professional wholesale customization service process, and how to use tin boxes to enhance brand exposure and customer loyalty, providing practical guidance for global buyers.

Why custom tin boxes = mobile billboards?

Tin boxes have their own "secondary communication" gene - the exquisite printed design makes consumers reluctant to discard them, but instead use them as storage jars, gift boxes, and even home decorations. When customers place tin boxes with brand logos on their desks, kitchens, or social occasions, your brand will gain continuous exposure. For example, international brands such as Disney and Nestle have long cooperated with Chinese custom printed tin box manufacturers such as Guangzhou Tianyi Metal Products, integrating IP images and product stories into the surface of tin boxes through high-precision offset lithography, making the packaging itself a social currency.

Guangdong suppliers: the core hinterland of global tin box manufacturing

Guangdong concentrates more than 80% of China's high-end tin box production capacity, leading the world with three major advantages:

Industry chain cluster effect: from tinplate raw materials to printing, molds, and stamping integration, Dongguan Lijin Packaging and other companies have more than 2,000 sets of mold libraries, supporting rapid proofing of any complex shape (samples completed within 7 days);

International quality control standards: Tianyi Metal and other customized printed tin box Guangdong suppliers have passed FDA, LFGB, EN71 and other certifications, and the materials are equipped with MSDS safety reports to meet European and American food-grade packaging requirements;

Flexible production: 15 automated production lines support a monthly production capacity of 5 million pieces, and can undertake customized orders as small as 1,000 pieces (MOQ), flexibly adapting to start-up brands and bulk procurement needs.

Decoding the global competitiveness of Chinese manufacturers

China's tin box factories are shifting from "OEM" to "design and manufacturing", with core capabilities including:

Innovative technology integration: Hongmao Tin uses A-grade tinplate substrate and imported printing equipment to achieve advanced effects such as gradient gold and embossed embossing;

Full-scenario product line: covering food (moon cakes/chocolate cans), gifts (holiday gift boxes), collectibles (limited edition metal cans) and other fields. Kaiping Zhenming Metal has even developed cross-border categories such as ice buckets and candlesticks;

ODM/OEM in-depth service: Chinese custom printed tin box manufacturers such as Lu'an Jinyu Metal provide full-process support from design draft optimization, 3D modeling to RoHS environmental testing to reduce customer development costs.

Data witnesses strength: The annual export volume of leading enterprises exceeds US$100 million, and products are exported to 150 countries, with a 35% increase in repurchase rate in the European market.

Key elements of professional custom printed tin box wholesale

To obtain cost-effective and differentiated tin boxes, you need to pay attention to four key points:

Minimum order quantity and cost balance:

Basic customization: MOQ 1000-3000 pieces (unit price $0.1-$0.69/piece);

Bulk optimization: Orders over 100,000 pieces can enjoy cost discounts, and delivery time is shortened to 30 days;

Printing process selection:

Process type---Applicable scenarios ---Advantages

Offset printing ---Complex patterns/gradient colors---Reduction degree up to 95%

Silk screen printing ---Metal texture/local UV ---Strong three-dimensional effect

Hot stamping/embossing ---Luxury/commemorative edition ---Tactile value-added

Full-link supporting services: Head suppliers such as Tianyi Metal provide "design-logistics-after-sales" one-stop hosting, including free samples, export label printing and sea freight packaging optimization;

Sustainability upgrade: Environmentally friendly coatings and recyclable tinplate materials (thickness 0.23mm) have become standard for professional custom printed tin box wholesale, in line with the green packaging policies of platforms such as Amazon.

How to start your tin box customization project?

Demands are accurately conveyed: provide brand VI, size specifications (such as round 190*55mm), and usage scenarios (food/gifts);

Proofing verification: use the supplier's free sample policy (such as Tianyi Metal supports free samples within 2 pieces) to test the actual effect;

Mass production guarantee: choose an ISO 9001 certified factory (such as Hongmao Tin) to ensure QC control from mold development to mass production.

Conclusion: Small tin box, big marketing

When packaging evolves from "container" to "brand touchpoint", customized tin box becomes a lever to pry consumers' minds. China's customized printed tin box manufacturers have an important position in the global value chain.

Immediately connect with the customized printed tin box Guangdong supplier to start your professional customized printed tin box wholesale project-let the product speak for itself and let the brand be seen everywhere!