This year we carefully created a PU leather handle coffee tin box for the coffee brand. The size is 185x136x85mm. It is made of food-grade tinplate and the material thickness is 0.23mm.

This year, Cosmetics Brands joined hands with our professional tin box manufacturer to create a cosmetic tin box with handle that combines beauty and practicality. This is not only a container for beautiful things, but also an ode to a refined attitude towards life.

The Xmas detachable candy balls is made of tinplate, the iron box is strong and durable. It is not easy to open directly, you can easily open the hemisphere without the string by pulling the string. The Christmas ball can be used as a candy jar, and the candy ball has enough space for candies, chocolates, trinkets, and small things. At the same time, its lovely shape and hanging ribbon are also perfect for Christmas tree decoration

Material and safety Food-grade tinplate material, light and durable, drop-proof and rust-proof, in line with food safety standards. The interior adopts environmentally friendly coating, no odor, and can directly contact food. Customized printing Full-surface high-definition printing: supports single-sided/double-sided customization of corporate logos, patterns, slogans or art designs. Process selection: silk screen printing, hot stamping, UV embossing and other processes are optional to enhance the brand texture. Applicable scenarios: employee benefits, event gifts, promotional gifts, campus customization, etc.

Our round tin cookie box is an elegant and practical packaging solution designed to keep your cookies fresh and beautifully presented. Made from high-quality tinplate, it offers excellent durability and protection against moisture and breakage. The smooth, classic round shape adds a touch of sophistication, making it perfect for gifts, festive treats, or everyday storage. With customizable designs, sizes, and finishes, this tin box not only preserves the delicious taste of your cookies but also enhances your brand’s image with eye-catching, reusable packaging.

This heart-shaped tin box is made from food-grade material, making it safe for storing a variety of candies and gifts. Perfect for the holiday season, this charming tin adds both function and holiday cheer to any celebration.

These discreet low profile rectangle tins feature a clean & fresh style that will remain modern for many uses to come. Our lightweight durable containers are made from high-quality material. Reliable hinge & seal for a perfect closure every time. General household organizing, crafts, homemade packaging, store spices, tea leaves, coffee beans, chocolates, mints, creams, balms, gels, jewelry, beads, sequins, recipe cards, arts, medicines, pills, lip balm, cosmetics, gifts, party favors, Double button locking hinged lid that offers great child resistant packaging.

Designed for exquisite chocolates, our custom food-grade rectangular chocolate tinplate boxes provide safe, beautiful and highly flexible packaging solutions. This packaging box is strictly made of high-quality tinplate materials that meet food contact safety standards (such as FDA/GB) to ensure that the contents are pure and uncontaminated. The classic rectangular design is not only simple and elegant in appearance and full of modernity, but also can efficiently utilize space, making it easy to stack, transport and retail display. The core advantage lies in its deep customization service - you can freely choose the box size, color (internal and external coating), pattern printing (high-definition color printing, hot stamping/silver, etc.), and lining material (such as food-grade white cardboard tray, PET blister tray, flannel, etc.), perfectly carrying and enhancing the value and protection of your brand chocolate. The sturdy iron box structure provides excellent sealing and moisture-proof performance, effectively extending the freshness and shelf life of chocolate, and is an ideal packaging choice for high-end chocolate brands, gift markets and baking industries.

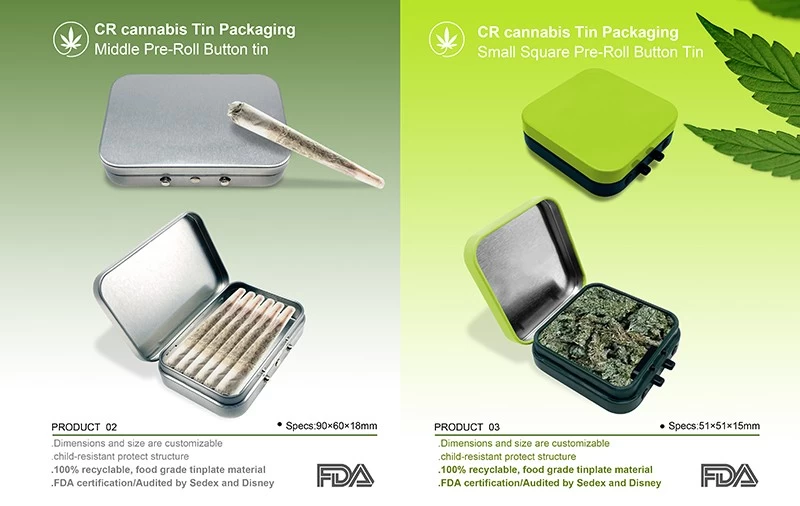

With the increasing attention paid to children's safety, more and more parents and companies have begun to pay attention to the design and quality of children's products. In daily life, childproof tin boxes, as a practical and safe packaging product, are widely used in the storage of cannabis, food, toys and school supplies. However, many consumers may be curious, why are these seemingly simple tin boxes expensive? This is not just a "packaging" problem, but a comprehensive reflection of safety, design, craftsmanship and other aspects. This article will answer the high price of customized childproof tin boxes china and explore how to optimize costs while ensuring safety and quality.

1. Special design requirements

Safety requirements: Customized child-proof tin boxes need special designs to ensure smooth edges and no sharp parts to prevent children from getting hurt when using them. This kind of detailed design will increase the difficulty and cost of production.

Structural complexity: Protective tin boxes usually require special opening and closing structures, such as snap-on design or enhanced sealing performance, to ensure that the box is safer and more durable.

2. Material cost

High-quality materials: The tin used for child-proof tin boxes needs to meet food grade or safety standards, and the cost of this material is usually higher than that of ordinary industrial-grade tin.

Environmental protection requirements: Many food products require the use of environmentally friendly materials and comply with relevant international standards (such as RoHS, REACH, etc.), which will also increase costs.

3. Production process

Complex manufacturing process: In order to ensure the quality and safety of child-proof tin boxes, multiple processing may be required, such as deburring, spraying non-toxic coatings inside and outside, etc.

Custom mold cost: The shape and structure of child-proof tin boxes are usually unique, and exclusive molds need to be designed and manufactured for each product, and the mold cost is usually high.

4. Printing and decoration

Personalized design: Customized childproof tins often require bright, attractive pattern printing, and this high-quality, multi-color printing process is costly.

Complex printing technology: If 3D embossing, UV printing, or matte/glossy effects are required, these processes will increase costs.

5. Production batch

Customized small batch production: If the order volume of customized childproof tins in China is small, the production cost of a single product will be relatively higher because the amortization cost of molds, designs, and production lines is high.

6. Certification costs

Quality certification: Children's products need to pass multiple certifications, such as toy safety standards (EN71) or FDA food grade certification, and the costs of these tests and certifications will also be included in the cost.

7. Transportation and packaging

High standard packaging: In order to prevent product damage during transportation, better packaging materials and methods are usually required.

Logistics costs: Customized childproof tins are heavy and bulky, and transportation costs may be high.

How to optimize costs?

A. Batch production: Increasing the production quantity can amortize mold costs and design costs.

B. Reasonably simplify the design: simplify the structure and decoration while meeting safety requirements.

C. Choose the right process: choose a more economical printing or manufacturing process based on the budget.

D. If you can provide more specific customization requirements, Guangdong Cannabis Tin Box Supplier can help you analyze whether there is a possibility of optimizing costs!